- Products

- the Control and I/O menu

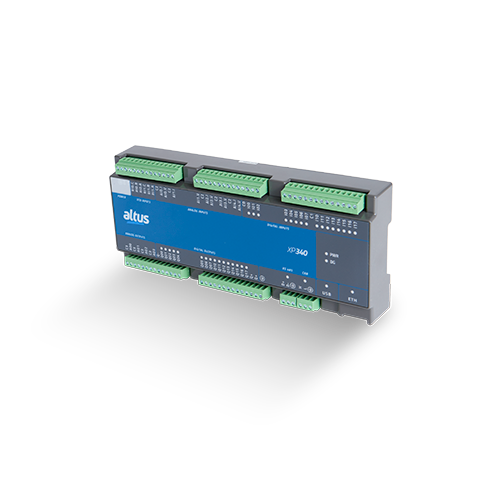

- PLC

PLC

Take control of your business with Nexto System PLCs

The system includes five lines of control equipment, offering exceptional performance, robust cybersecurity, and reliable connectivity for even the most advanced industrial automation applications worldwide.

Meet the features available in the Nexto System

High performance and adaptability

Preemptive and multitasking, Nexto CPUs are built to handle even the most sophisticated applications. Powered by advanced RISC PowerPC and ARM processors, ranging from 32 to 64 bits, these units deliver high performance with low energy consumption, eliminating moving parts and increasing MTBF.

Nexto PLCs can process over 145,000 Boolean instructions or up to 500 PID loops per millisecond, perform complex arithmetic operations, and execute advanced control functions crucial for full automation of machines and industrial processes.

Advanced programming environment

All Nexto products use MasterTool IEC XE software for programming and configuration—an integrated environment for programming, debugging, configuration, and application simulation. Based on CODESYS technology, this software supports every stage of project development, from small-scale to large-scale applications, speeding up deployment while reducing engineering and commissioning costs.

With a user-friendly interface and intuitive design, the software is easy to learn and navigate. It serves as a unified control hub with a modern programming environment, supporting six programming languages as outlined in the IEC 61131-3 standard, meeting a wide range of technical requirements and preferences.

Versatility and scalability for growing operations

Smart and versatile, Nexto processing units are designed with features that allow the creation of network variables. This capability enables users to generate or modify specific variables in one PLC and replicate them across other controllers on the network, cutting down on maintenance time and engineering hours during system development.

Baseado em Ethernet determinística, o barramento interno da linha NX pode ser expandido em múltiplos bastidores remotos, sem perda de desempenho. Uma CPU pode controlar até 320 pontos I/O em um único bastidor e até 24 bastidores remotos podem ser conectados ao bastidor local. Igualmente, os CLPs da linha XP contam com diferentes opções de módulos de expansão para agregar mais pontos de I/O às suas aplicações.

See more about the I/O module options available in the Nexto System

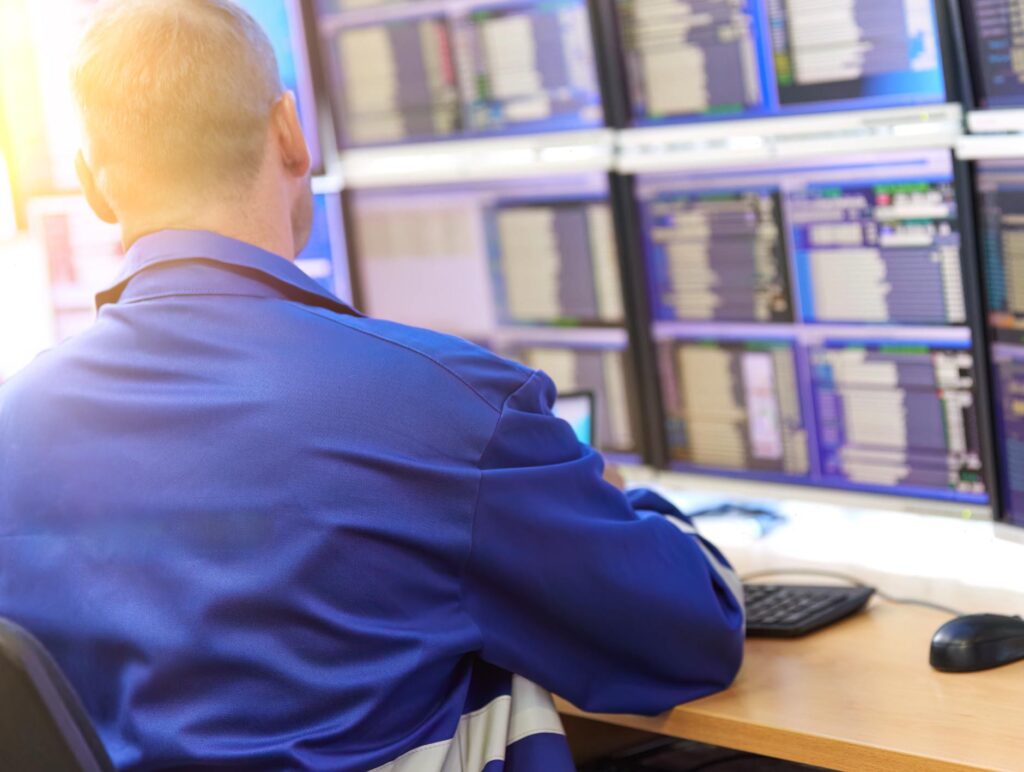

Built-in supervision capabilities

Para dar mais flexibilidade e agilidade no desenvolvimento de aplicações de pequeno e médio porte, a linha Nexto conta com o WebServer, sistema para criação de telas de supervisão e monitoramento sem a necessidade de um software SCADA. Disponível nas CPUs NX3005, NX3008 e XP340, a ferramenta é embarcada na memória do CLP e pode ser acessada através do navegador Web de qualquer dispositivo (computador, tablet ou smartphone) conectado à rede.

Advanced data collection and management

Designed to meet modern demands for security and connectivity, Nexto PLCs come equipped with advanced features for secure and dynamic data collection. The latest CPUs support FTP connections, enabling seamless data exchange with servers using this protocol. This functionality allows remote access to data generated by the controllers.

Additionally, all Nexto controllers support the MSSQL_CLIENT functional block, providing direct access to and writing capabilities in Microsoft SQL databases.

Built-in cybersecurity against attacks

Controladores como a CPU NX3008 e os CLPs da linha XP também contam com VPN embarcada, recurso que permite criar um túnel privado de conexão direto com a aplicação. A funcionalidade permite acessar a rede de controle do seu negócio de forma remota e completamente segura. Para aumentar ainda mais segurança desses produtos, os controladores citados também contam com um firewall integrado.

Click here to download the cybersecurity manual developed by Altus’ R&D team