- Segments

- Manufacturing Industry

- Pharmacist and Health

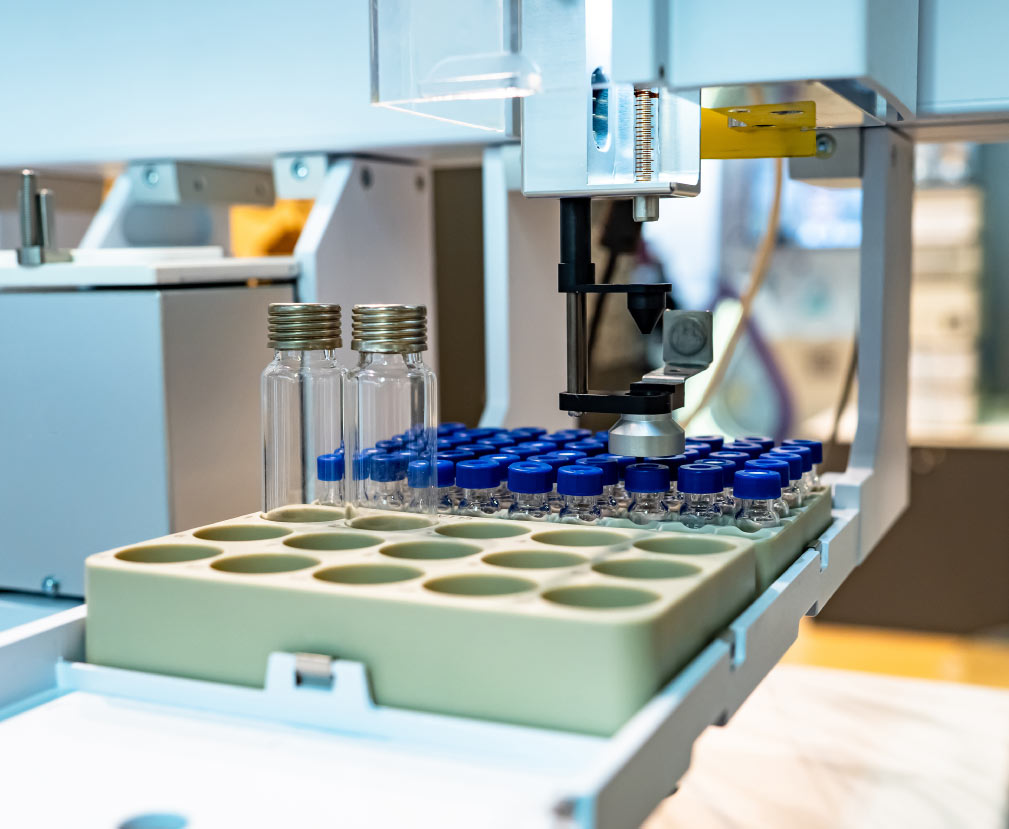

High-precision integrated solutions for the Pharmaceutical Industry

From lab to large-scale production, enhance control and monitoring with Altus products and engineering solutions

With over four decades of experience in the global technology sector, Altus has built a deep expertise in process automation for the pharmaceutical industry. By leveraging this extensive knowledge alongside the cutting-edge technology of Nexto PLCs, we offer robust solution that not only optimizes production but also ensures full compliance with the industry's strict safety and quality standards.

Ask for a advisory

Do you want to implement your current project with us? We will be happy to advise you!

Projects and solutions for the sector

Our solutions for this industry

Accurate and standardized production in the Pharmaceutical Industry

By using the programmable controllers from the XP series, you can continuously monitor dosing parameters, such as ingredient volume and flow rate, in pharmaceutical, biopharmaceutical, and cosmetic industry processes. The advanced technology embedded in Nexto products also allows you to instantly adjust parameters according to process demands. This results in more precise and homogeneous dosing, preventing waste and ensuring compliance with production specifications.

The built-in communication features of Altus compact PLCs also enable seamless integration with other systems, giving you comprehensive, synchronized control over the entire production cycle. This not only boosts operational efficiency but also provides the flexibility needed to adapt to changing demands and process variations in the chemical industry.

Learn more about the compact and IoT-ready PLCs from the XP series

Monitoring variables, quality control and traceability

Environmental control is crucial in the pharmaceutical industry. By using Nexto System programmable controllers to run your production facilities, you gain precise control over key variables such as temperature, humidity, pressure, and speed at each stage of the process.

Nexto PLCs also ensure rigorous quality control by monitoring critical factors like pH levels, active ingredient concentrations, and the physical properties of products. This automated approach guarantees consistent, high-quality production, improving efficiency and minimizing waste.

Furthermore, the ability to closely monitor the entire production process enhances batch traceability, enabling quick identification and resolution of potential issues. This is vital for maintaining regulatory compliance and ensuring product quality.

Precise solutions for cleaning and sterilizing equipment

Effective cleaning and sterilization are essential to ensuring the safety and quality of pharmaceutical products. Nexto programmable controllers allow you to create automated cleaning and monitoring routines that remove microorganisms and contaminants that could compromise product integrity. This helps meet regulatory requirements, reduces contamination risks, and ensures the effectiveness of your pharmaceutical products.

Nexto PLCs not only safeguard product quality but also enhance operational efficiency. By automating these critical routines, you significantly reduce cleaning and sterilization times, minimize contamination risks, and lower operational costs—allowing you to focus resources on other essential aspects of production.